Description

Overview:

The electrical resistance (ER) technique is an “on-line” method of monitoring the rate of corrosion and the extent of total metal loss for any metallic equipment or structure. The ER technique measures the effects of both the electrochemical and the mechanical components of corrosion such as erosion or cavitation. It is the only on-line, instrumented technique applicable to virtually all types of corrosive environments.

Although universally applicable, the ER method is uniquely suited to corrosive environments having either poor or non-continuous electrolytes such as vapors, gases, soils, “wet” hydro-carbons, and non aqueous liquids.

Examples of situations where the ER approach is useful are:

- Oil/gas production and transmission systems

- Refinery/petrochemical process streams

- External surfaces of buried pipelines

- Feed water systems

- Flue gas stacks

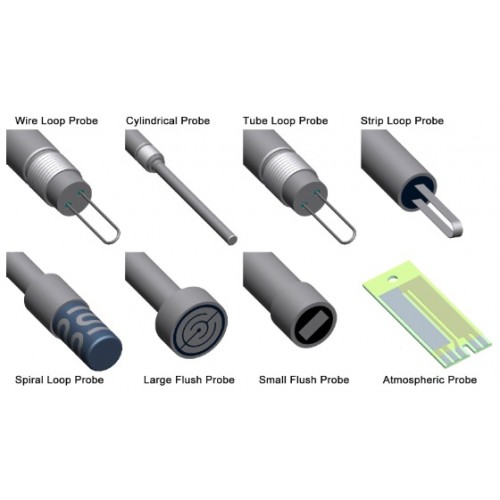

Architectural structures An ER monitoring system consists of an instrument connected to a probe. The instrument may be permanently installed to provide continuous information, or may be portable to gather periodic data from a number of locations. The probe is equipped with a sensing element having a composition similar to that of the process equipment of interest.

Refer to attached data sheets for available probes & instruments for ER Monitoring.